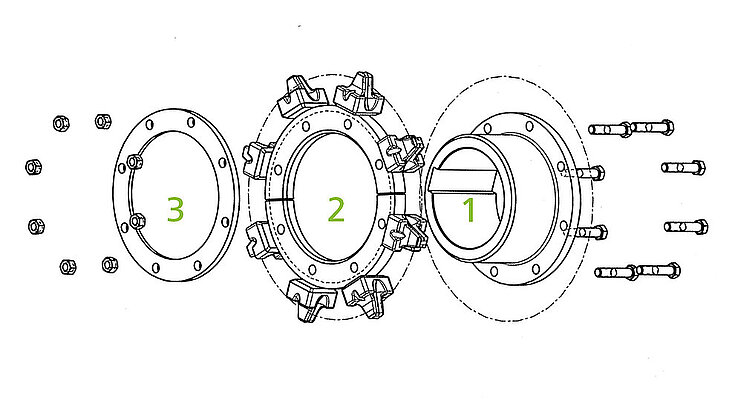

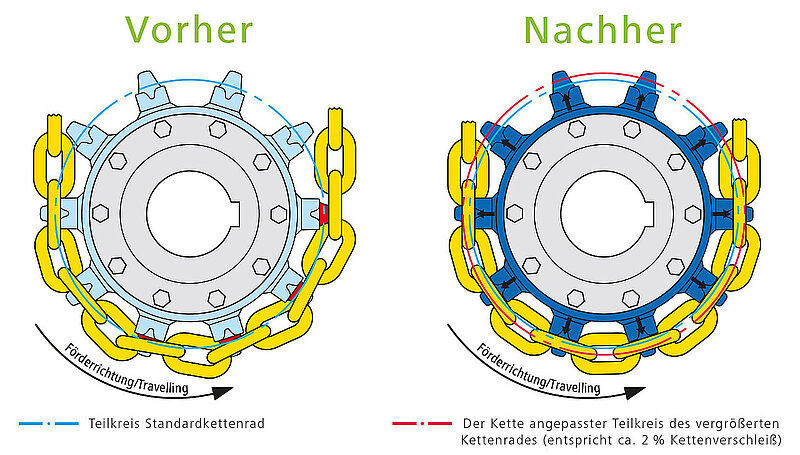

Inserting a new tooth segment with increased link contact / larger pitch circle compensates for chain wear and increases the life cycle of the complete sprocket in your conveyor system. Sprocket discs and individual teeth, optimally adapted to the percentage chain extension given at the time of replacement. Available in the dimensions 14 × 50 to 38 × 144 for all multi-part sprockets.

Areas of application

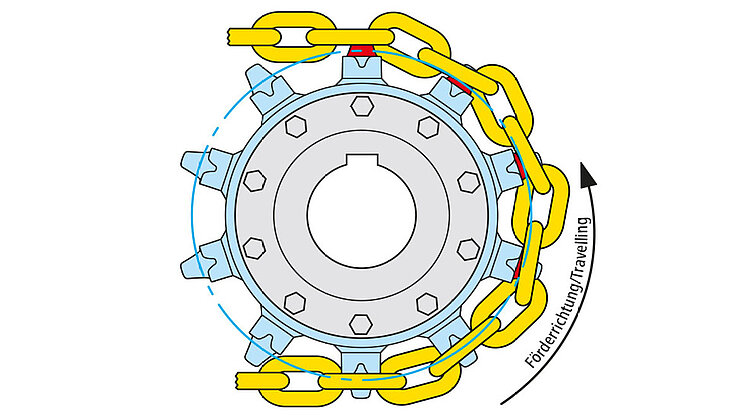

Before: Chain runs on

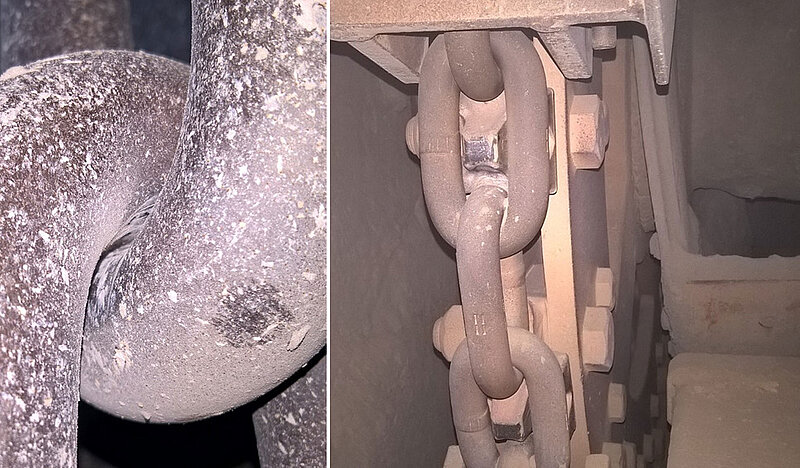

Indicators for excessively worn chain:

- Uneven running

- Crescent formation on rear tooth flank

- Backlash used up

- Strong vibration on the drive

- Chain only falls onto the chain link support of the teeth after several teeth

After: The chain wear is compensated for by inserting a new tooth segment with a larger pitch circle.

The solution:

- Inverted tooth sprockets with increased link contact of the tooth segments

- Replaceable tooth segments / individual teeth increase the life cycle of the complete sprocket

RUD Fördertechnik - Plant & mechanical engineering

RUD Fördertechnik - Anlagen & Maschinenbau offers you a wide range of systems, equipment and solutions for your application.

We design and manufacture elevators, continuous conveyors, chain conveyors, bucket elevators or scraper chain conveyors, preferably based on round steel chains as a means of traction. If required, we also use link chains and belts.

Our engineers have a broad background knowledge and support you as a competent partner in solving your individual conveying task. On request, RUD Service will visit you on site and support you with the installation, conversion or maintenance of your system/machine.