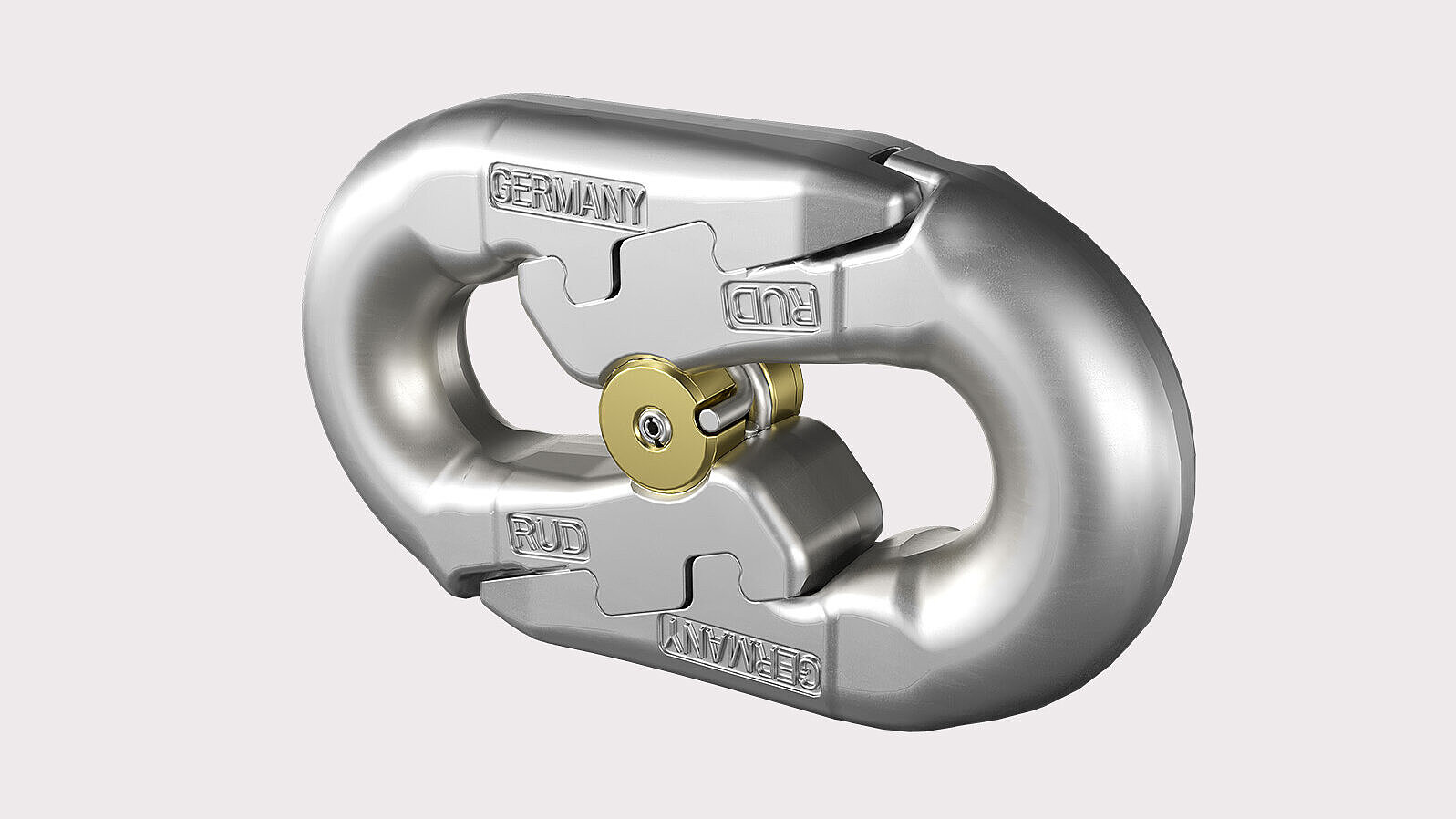

Compared to other apron conveyor systems, the RUD apron conveyor system is tight during both the straight and deflecting conveyor sections. This system was developed on the basis of the proven round steel chain and is matched to it.

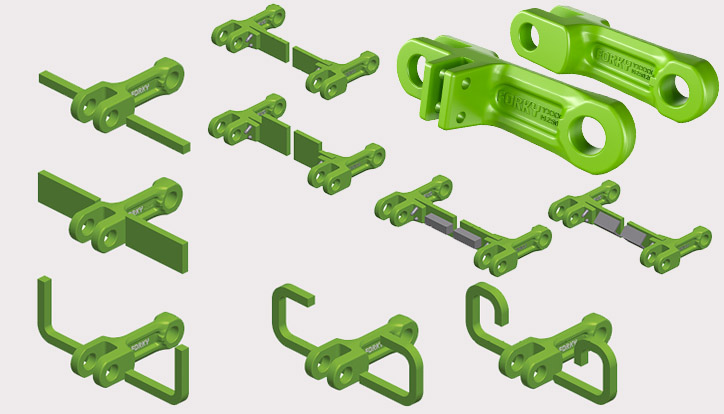

With dry de-ashing, in contrast to wet de-ashing, the conveyed material is not scraped across the trough floor, but is carried by plates connected to the conveyor chains, which in turn are removed in the conveyor housing. This is done via rollers and/or, if required, via rails. The conveyor chain is protected by guide plates that protrude over the side walls of the plates.

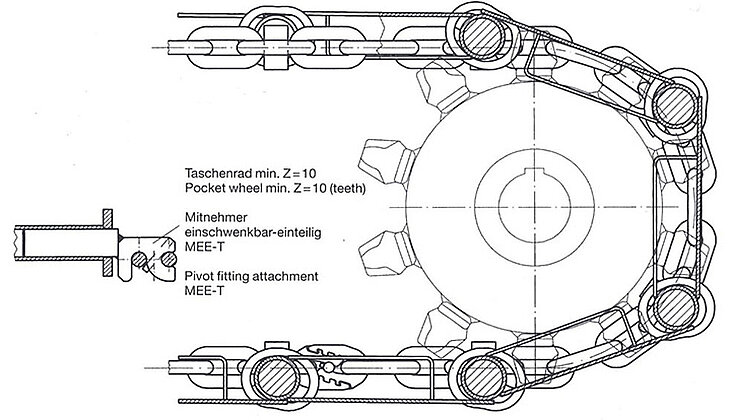

The conveyor chain in the apron conveyor is driven by externally toothed chain wheels (pocket wheels), which are more tolerant of longitudinal wear of the chain than the internally toothed wheels.

Depending on the angle of the ascending part of the conveyor, conveying capacities of around 5 t/h to around 70 t/h can be achieved. Capacities of 100 t/h have already been realized. The conveyor width is designed for 2000 mm.

Common conveyor speeds are 0.01m/s....0.07m/s; rarely higher than 0.1 m/s and are realized with adjustable electromechanical or hydraulic drives.

This principle results in a number of advantages.

Areas of application

Used in the following industries:

- Mining

- Power plant industry

- Tunnel construction

- Iron and steel works

- Stone / earth industry

- Chemical industry

- Recycling industry

- Cement industry

→ For conveying bulk materials and unit loads in power plants

→ Use as recycling plants

→ Use in building material plants

→ In particularly heavily loaded areas

→ etc.

Advantages

- Reduction of the friction width in the conveyor run and therefore a smaller chain size in individual cases with comparatively the same conveying capacity

- Conveyor chain does not run in the conveyed material and is therefore subject to less wear than with wet ash removal in comparison

- Relatively insensitive to large lumps of ash, which could possibly detach from the boiler wall during soot blowing

- Even more maintenance-friendly compared to the already low-maintenance chain equipment of the scraper wet ashtray

- With a RUD apron conveyor, significantly lower construction heights of dry scrubbers can be realized than with other design principles

- Closed plate cover over the entire service life

- No opening of the plate at the deflection

- Short pitch, low polygon effect

- Low overall height due to small sprocket diameter - Robust, simple design with high plate bending stiffness