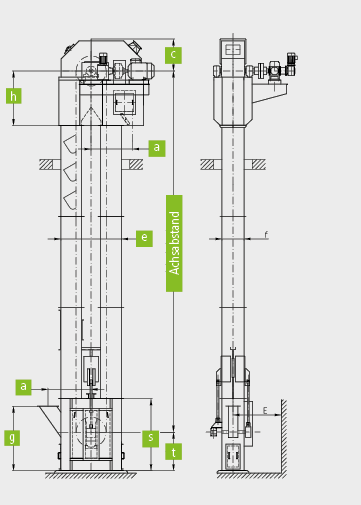

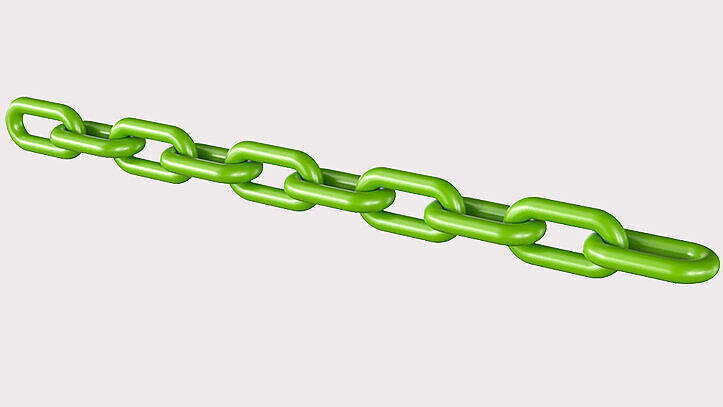

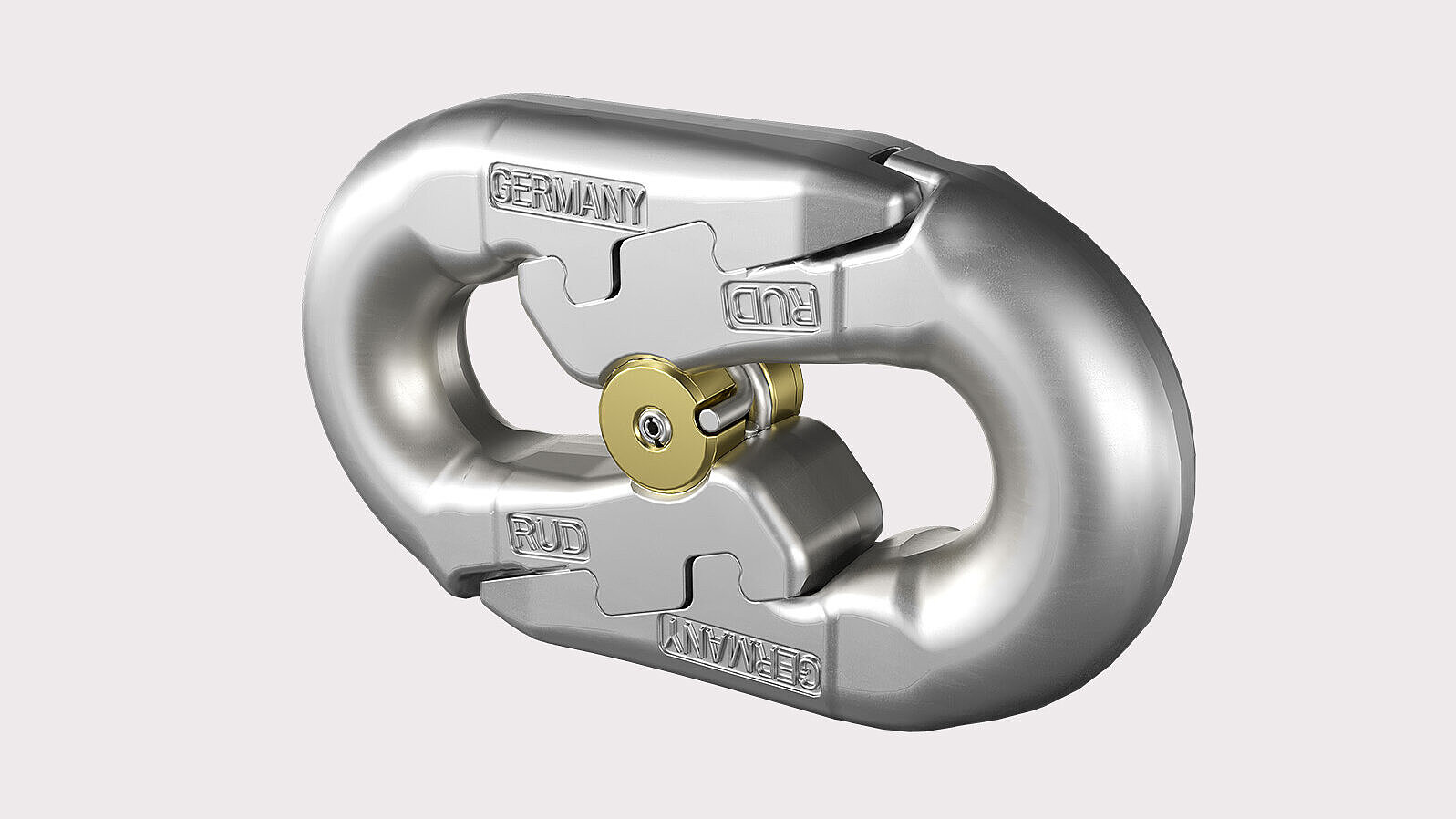

The bucket elevator housings are self-supporting, but require horizontal guides at a maximum distance of 15 m and below the bucket elevator head. The bucket elevator head consists of a lower part with flaps for adjusting the discharge tongue. Above this is a multi-part, removable hood with inspection flap. The drive shaft is supported in pedestal bearings, the shaft passages are sealed with relubricatable radial shaft seals. The bracket for supporting standard drives is attached to the side of the lower part of the head. A maintenance platform and a mounting bracket can be attached to the housing if required. The drive consists of a geared motor that can preferably be connected to a frequency controller for maintenance purposes. For higher power requirements, we recommend a drive unit consisting of a helical bevel gearbox, optionally with auxiliary drive, and a standard motor. The starting characteristics can be optimized via a hydraulic clutch or an electric soft start. The double or single chute is manufactured as a torsion-resistant sheet metal housing in standardized partial lengths with connecting flanges. The maintenance and assembly door with opposite assembly flap should be arranged in the housing of the rising column, approx. 0.8 m above a platform, if possible. The bucket elevator foot is optionally designed with oil-filled internal bearings or external pedestal bearings. With external bearings, the shaft openings are sealed with stuffing boxes made of cast iron. Large mounting flaps and cleaning flaps are provided on both sides. The chain pre-tension is generated via a weighted or spring-loaded spindle tensioning device. Depending on the type of chain, the RUD drive sprockets are toothless chain rollers with replaceable, highly wear-resistant segments or toothed chain sprockets with replaceable, highly wear-resistant teeth, while the RUD return sprockets are chain rollers with replaceable, highly wear-resistant segments or races.

Dimensions & conveying capacities

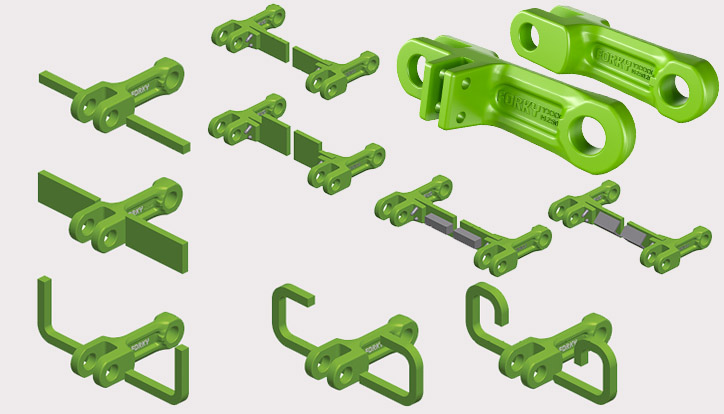

The buckets are manufactured in accordance with DIN or our factory standard. Steel, stainless steel or rubber are available as materials. The buckets are attached by means of plug-in attachments or angle brackets. The chains are hardened special developments made of alloyed special steel in a highly wear-resistant design. Link chains are also used as double or central chains. The safety devices, consisting of a speed monitor and level indicator, monitor the operating status of the bucket elevator.