RUD Remote Service - We support you live and direct

For a smart connection with your sponsors

Analyze critical conveyors or infrastructures and detect dangerous operating conditions such as excessive heat, overfilled discharge hoppers, abnormal speeds, jammed rollers or worn tensioning paths.

Improve process reliability through targeted analysis:

RUD COCKPIT Basic Package 1 provides a forecast of the remaining service life of the chain equipment. RUD COCKPIT Basic Package 2 provides a differentiated remaining service life of the chain equipment based on real-time data of the chain extension (in percent).

RUD COCKPIT supports preventive maintenance and service planning:

You get a precise overview of the conveyor's operating conditions right from the start. This allows conclusions to be drawn as to why the service life of chain equipment is reduced (due to different speeds, jammed rollers, large number of work cycles, etc.).

Connect your conveyors to the RUD COCKPIT and benefit from our experience. Analyze the availability of your conveyor.

Areas of application of the RUD COCKPIT Service

- Vertical conveyors (e.g. bucket elevators)

- Horizontal conveyors (e.g. scraper conveyors for ash removal or other applications)

Focus:

- Analysis of critical operating conditions = transparency!

- Knowledge-based consulting for conveyors

- Fact-based budget planning

Get information about:

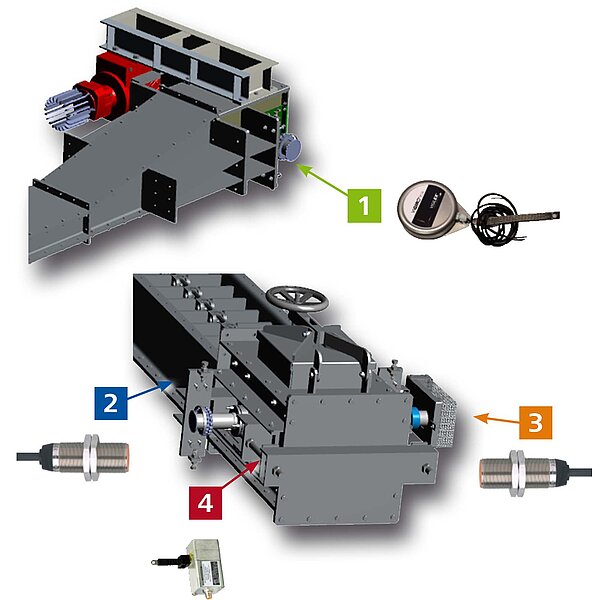

1. Speed analysis / operating hours (Contains information about the speed and operating hours of the machine)

2. Chain life prediction based on RUD model (Collects relevant information)

3. Chain breakage monitoring (This sensor signals when the expansion shaft is not rotating)

4. Chain wear on chain loop / slippage analysis (Collects information on the remaining tension distance)

5. Chain running analysis (Signals ascending chain links)

6. Power analysis (hydraulic power only in a first step) (Collects information on the driving force of the machine)

7. Temperature sensor (Checks the temperature)

8. Overfilling of the discharge chute (Collects signals of overfilling of the machines)

9. SOI Detects stuck underwater rollers (This sensor informs you if the underwater roller is not rotating)

Advantages of the RUD COCKPIT service at a glance

Your benefits at a glance:

- Automated, continuous measurement

- No conveyor stops required. No production downtime.

- Real-time data. Validated information at any time

- Fact-based budget planning possible

- Availability of data on all mobile devices for quick decisions.

- Web-based access to your data, no need to download an app

- Permanent availability of data through cloud application

- The core function is independent usability for any type of conveyor

- Secure access with personalized password

WITH RUD COCKPIT you are able to:

- Detect dangerous operating conditions (e.g. excessive heat, excessive speeds, jammed rollers, used up tension travel).

- Analyze the expected service life and operating times.

- Analyze the wear of chain equipment by measuring the elongation.

- Allows you to conclude why the service life of chain equipment is reduced (e.g. due to excessive speeds, jammed rollers, etc.).

RUD COCKPIT basic packages

| No. | Function of the sensors | Base Packet 1 Forecast model | Base package 2 Direct model | |

|---|---|---|---|---|

| 1 | - Speed analysis - Operating hours | ✔ | ✔ | |

| 2 | Chain service life forecast based on RUD model | ✔ | ✔ | |

| 3 | Monitoring of chain breaks | ✔ | ✔ | |

| 4 | Chain wear measurement on a chain loop* | ✔ |

* Both pieces of information lead to a more detailed expected remaining service life of the chain equipment

RUD COCKPIT web interface

RUD's revolution is part of the "Internet of Things"! You too?

- Manage all your machines from one place

- Flexibility for new devices

- Easy login from anywhere in the world

- Responsive design for your mobile device

The following hardware end devices can be used to visualize alarms and view the web application:

- Desktop PC

- Smartphone

- Tablet computer

- Laptop computer

- LAN / WLAN access and a mobile network are required